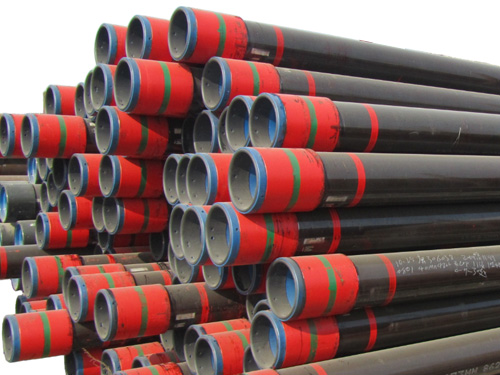

P110 Oil Casing

P110 Oil Casing is a typical representative of high-strength casing in the API 5CT standard. "P110" represents its minimum yield strength of 110ksi (approximately 758MPa), known for its high strength and toughness. It is widely used in medium and deep wells as well as medium and high pressure oil and gas wells, with a market share of about 15%.

Performance and Material

P110 casing is made of high-strength alloy structural steel (such as 42CrMo), which is quenched and subjected to high-temperature tempering heat treatment (850 ℃ quenching+600 ℃ tempering). The yield strength is 758-965MPa, the tensile strength is ≥ 862MPa, the elongation is ≥ 16%, the impact energy is ≥ 35J, and the strength is 37% higher than N80. It can withstand severe pressure fluctuations. The upper limit of temperature resistance is 150 ℃, and the corrosion resistance is intermediate. It can adapt to environments containing low concentrations of CO ₂ (≤ 0.3%), but its sulfur resistance still needs special treatment (such as P110SS sulfur resistant model).

Structure and specifications

Mainly made of seamless steel pipes, with API standard threads (LTC/BTC) processed at the ends. High end models are equipped with special threads for gas sealing (such as VAM TOP), with a sealing pressure of ≥ 40MPa. Common specifications: outer diameter 139.7mm-273.1mm, wall thickness 7.72mm-12.65mm, single length 6-12m, connected to a complete set of pipe columns through couplings, weight about 10% heavier than N80 of the same specification.

Production process

After hot rolling and perforation, the tube blank is precision formed by cold rolling. The heat treatment requires strict control of the cooling rate (≥ 50 ℃/s) to obtain a uniform martensitic structure. The thread processing adopts a five axis linkage CNC machine tool, with a tooth profile error of ≤ 0.01mm, and the surface is treated with nitriding to improve wear resistance. The production cycle is 20% longer than N80, and the cost is 40% -50% higher.

Application scenarios

Medium to deep wells with a depth of 3500-5000 meters;

High pressure oil and gas wells (wellhead pressure 20-35MPa);

Horizontal casing for shale gas development (capable of withstanding high hydraulic fracturing pressure);

Replace some Q125 casing in medium and high voltage scenarios, balancing performance and cost.

+86-15533769121

Jango

jango@yuntaopiping.com

Beixiaozhuangzi Industrial Zone, Mengcun Hui Autonomous County

Copyright © 2025-2026 http://www.yuntaopiping.com. All Rights Reserved Yuntao Piping Group.,Ltd.Copyright