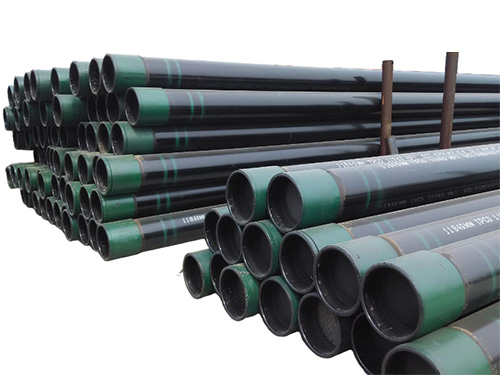

API J55 Oil Casing

API J55 Oil Casing is the most basic low strength casing in the API 5CT standard, with "J55" representing a minimum yield strength of 55ksi (approximately 380MPa). It belongs to the low strength level with K55 and has become the entry-level choice for shallow and low-pressure oil and gas wells due to its extreme economy, with a global market share of over 20%.

Performance and Material

The J55 casing is made of ordinary carbon steel (such as 20 # steel) and undergoes normalizing heat treatment (850 ℃ normalizing+air cooling). The yield strength is 380-552MPa, the tensile strength is ≥ 517MPa, the elongation is ≥ 22%, and the plasticity is better than K55, but the impact toughness is slightly lower (≥ 22J). Its temperature resistance upper limit is ≤ 110 ℃, and its corrosion resistance is at the basic level. It is only suitable for completely neutral medium environments (without H ₂ S, CO ₂) and requires external anti-corrosion coatings (such as epoxy coal tar) to extend its service life in humid environments.

Structure and specifications

Most of them are straight seam submerged arc welded pipes (large diameter) or seamless steel pipes (small and medium diameter), with API standard short circular threads (STC) processed at the ends, and an airtight sealing pressure of ≥ 20MPa. Common specifications: outer diameter of 114.3mm-339.7mm, wall thickness of 5.21mm-11.99mm, single length of 6-12m, connected to a complete set of pipe columns through couplings, with a weight basically the same as K55 of the same specification.

Production process

The simplest process: steel plate rolling welding (straight seam) or hot rolling perforation of pipe blank (seamless), after normalizing treatment to eliminate internal stress, thread processing accuracy meets API 5B standard, and only simple rust removal and painting are done on the surface. Due to the lack of alloy element addition and fine heat treatment, the production cycle is 10% shorter than K55, and the cost is 5% -8% lower, making it the category with the lowest manufacturing cost among all API sleeves.

Application scenarios

Ultra shallow oil and gas wells with a depth of ≤ 1500 meters (such as shallow natural gas wells and shallow oil reservoirs);

Low pressure water well, injection well (wellhead pressure ≤ 8MPa);

Surface casing of oil and gas wells (temporarily isolated from surface soil layer, recyclable later);

The wellbore support for non exploitation drilling (such as geological exploration wells).

+86-15533769121

Jango

jango@yuntaopiping.com

Beixiaozhuangzi Industrial Zone, Mengcun Hui Autonomous County

Copyright © 2025-2026 http://www.yuntaopiping.com. All Rights Reserved Yuntao Piping Group.,Ltd.Copyright