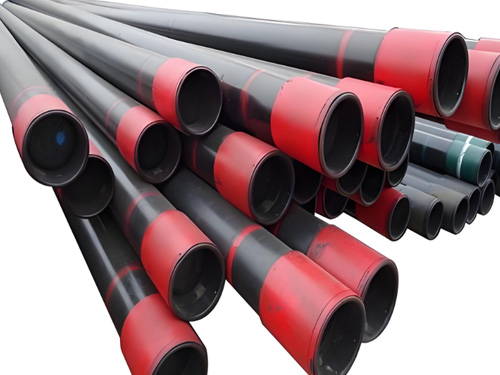

Q125 Oil Casing

Q125 Oil Casing (Q125 oil casing) is a high-strength oil casing in the API standard. "Q125" represents a minimum yield strength of 125 ksi (approximately 862 MPa), with performance between conventional N80 and ultra-high strength V150. It is suitable for deep wells and medium to high pressure oil and gas wells, balancing strength and economy.

Performance and Material

The Q125 casing is made of medium alloy quenched and tempered steel (such as 25CrMo, 30CrMnSi), which has undergone quenching and tempering heat treatment (830 ℃ quenching+520 ℃ tempering). The yield strength is 862-1034MPa, the tensile strength is ≥ 965MPa, the elongation is ≥ 16%, and the toughness is better than V150 (impact energy ≥ 40J). The sulfur resistance meets the requirements of HIC and SSC testing (no cracks in H ₂ S containing environments), and can adapt to acidic formations, but the upper limit of temperature resistance is slightly lower (≤ 170 ℃).

Structure and specifications

Adopting seamless steel pipe structure, the end is processed with API standard threads (such as STC, LTC), and some high-end models are equipped with special threads (such as Tenaris Hydril), with an airtight sealing pressure of ≥ 55MPa. Common specifications: outer diameter of 114.3mm-273.1mm, wall thickness of 6.98mm-11.51mm, single length of 6-12m, connected to a complete set of pipe columns through couplings, weight 8% -10% lighter than V150 of the same specification.

Manufacturing process

After hot rolling and perforation of the tube blank, the dimensional accuracy (outer diameter tolerance ± 0.75mm) is refined by cold drawing. The thread processing adopts CNC equipment, with a tooth profile error of ≤ 0.03mm. The surface is treated with phosphating and painting to enhance its corrosion resistance. Compared with V150, the heat treatment temperature is slightly lower, the production cycle is shortened by 15%, and the cost is reduced by about 20%.

Application scenarios

Suitable for deep wells and medium to high pressure oil and gas wells with a depth of 3000-5000 meters (such as tight oil wells in Xinjiang Oilfield), specific functions:

Support the wellbore and withstand moderate formation pressure;

Isolate oil and gas reservoirs from water layers to prevent cross flow;

Suitable for medium and high pressure mining conditions (wellhead pressure 5-30MPa), with better cost-effectiveness than V150.

+86-15533769121

Jango

jango@yuntaopiping.com

Beixiaozhuangzi Industrial Zone, Mengcun Hui Autonomous County

Copyright © 2025-2026 http://www.yuntaopiping.com. All Rights Reserved Yuntao Piping Group.,Ltd.Copyright